In the fast-paced world of seafood processing, consistency and efficiency reign supreme. Enter the marvels of fish grading and sorting machines, revolutionizing the industry by automating the once-laborious task of fish classification. This article delves into the intricate wokings of these machines, exploring their benefits and the various technologies they employ.

Table of Contents

ToggleWhat are Fish Grading and Sorting Machines?

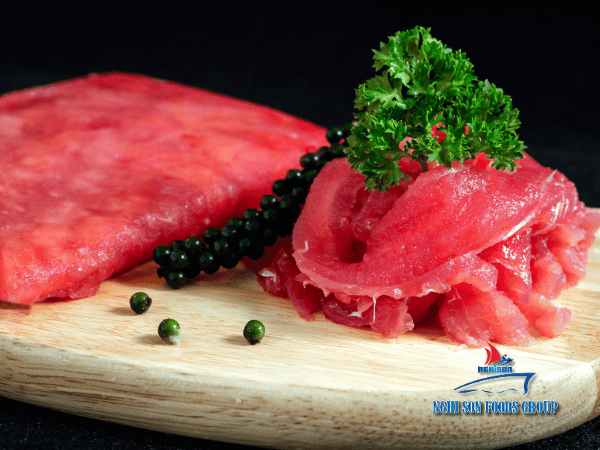

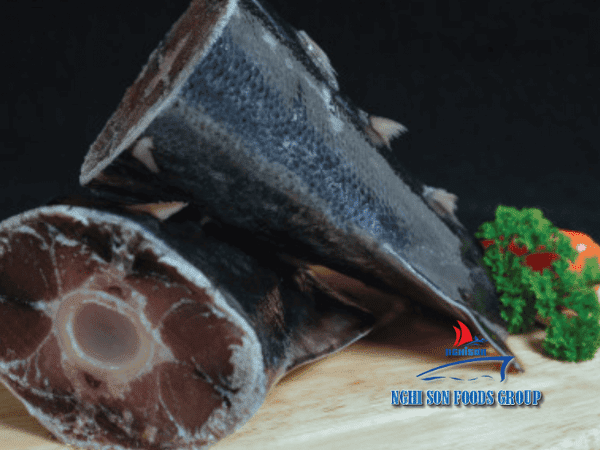

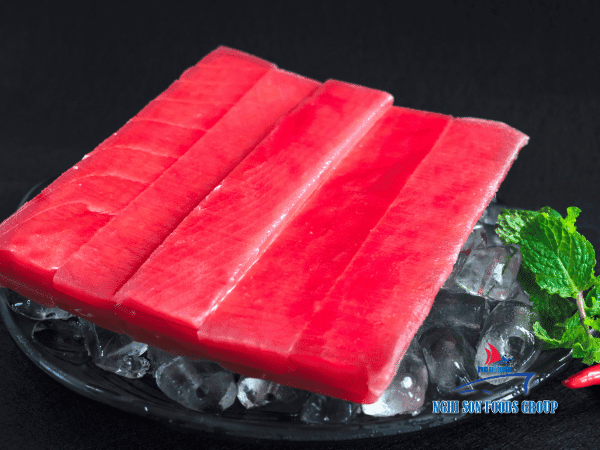

Imagine a conveyor belt brimming with fish, all destined for different fates based on size, weight, and even species. Fish grading and sorting machines make this a reality. These ingenious machines utilize a combination of sensors and mechanical components to meticulously categorize fish, ensuring they reach the appropriate processing stations.

Benefits of Fish Grading and Sorting Machines

- Enhanced Efficiency: Automating fish grading significantly reduces processing times and labor costs.

- Improved Consistency: Machines eliminate human error, leading to consistently sized and graded fish for standardized portions and pricing.

- Reduced Waste: Accurate sorting ensures fish are directed to the most suitable processing lines, minimizing product downgrades and waste.

- Increased Product Quality: Gentler handling by machines minimizes damage to the fish, preserving its quality and visual appeal.

- Traceability and Data Collection: Modern machines can record data on weight, size, and even species, facilitating traceability and quality control.

Technological Marvels Behind the Machine

Fish grading and sorting machines employ a variety of technologies to achieve their remarkable feats. Here are some of the most common:

- Weight Grading: Fish pass over conveyor belts equipped with weight sensors, triggering mechanisms that divert them to designated weight categories.

- Length and Width Grading: Cameras with machine vision systems capture fish dimensions, prompting sorting based on pre-programmed size parameters.

- Species Recognition: Advanced systems leverage image recognition software to differentiate between fish species based on visual characteristics.

- Color Sorting: For specific applications, color sensors can sort fish based on skin color variations, indicating fat content or freshness.

Choosing the Right Fish Grading and Sorting Machine

The ideal machine for your seafood processing plant depends on several factors, including:

- Type of Fish Processed: Different fish require specific sorting criteria (size, weight, species).

- Processing Capacity: Machine capacity needs to match your production volume.

- Desired Level of Automation: Consider the level of automation required for your operation.

- Budget: Grading and sorting machines range in price and complexity.

The Future of Fish Grading and Sorting

The future of fish grading and sorting is brimming with exciting possibilities. Advancements in artificial intelligence (AI) and machine learning (ML) are paving the way for even more sophisticated sorting based on factors like fat content, freshness, and even potential health risks. With these advancements, fish grading and sorting machines will continue to optimize efficiency and ensure the highest quality seafood reaches consumers worldwide.